Which is the best caster wheels for heavy load?

This needs to be analyzed in detail according to the use environment and load-bearing requirements. It does not mean that the bigger the size and the stronger the load-bearing capacity, the better.

First of all, it is necessary to determine the environment and load requirements of the use.

In terms of high load in a broad sense, each application classification has its high load range according to the application range of casters.

For example, furniture casters, 2 inch brown TPR double-wheel casters with a load of up to 176 pounds. For plastic casters with the same size of only 33 pounds, TPR casters are high-load. Applying them to the scene of plastic casters is completely competent. , carrying capacity far exceeds the latter. However, this is not the best heavy load caster wheels. Due to the excessive load surplus, higher costs are brought, and the cost performance is not high.

In terms of high load in a narrow sense, the use environment and load requirements are equally important.

For example, among the heavy duty casters, there are many styles with the same size and the same load capacity, so it is even more necessary to choose the appropriate casters in a targeted manner.

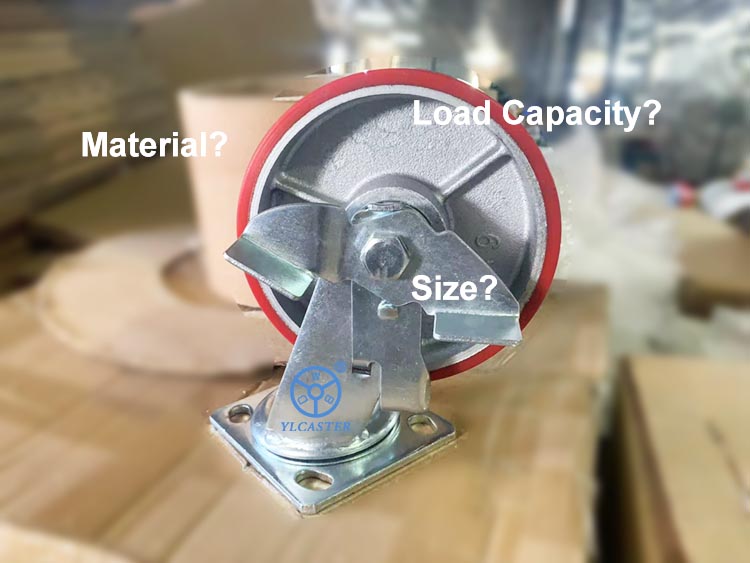

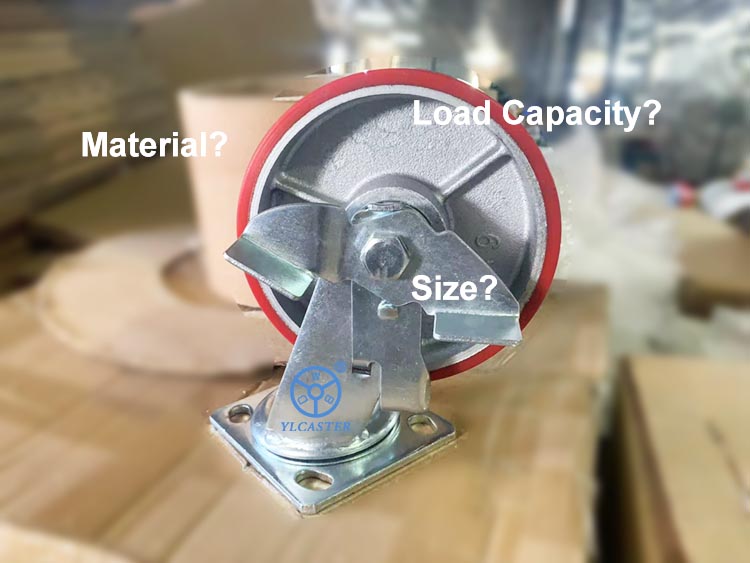

If you pull a flat trolley and often do outdoor activities, the loads are usually heavy. Heavy duty iron core polyurethane casters have won your favor due to their excellent wear resistance. However, the outdoor ground is not flat, and the polyurethane tire tread is terrible after falling down many times, and new wheels will soon need to be replaced. Moreover, the price of polyurethane casters themselves is not cheap, so it is very uneconomical. At this time, casters with good shock resistance, pneumatic casters and elastic rubber casters should be selected. Of course, the premise is that they meet your load requirements. It is also inappropriate to choose casters with a load capacity that just meets the standard, which will keep them in high-intensity working conditions and greatly shorten their service life.

We all know that the larger the size of the caster of the same type, the higher the load capacity, and the less effort it takes to turn it under load. So if we choose a large size caster, is it the best caster wheel for heavy load?

Not so. Excessive size and load will cause high cost and waste, and bring a higher center of gravity, easy to dump, and it is not suitable for machines or equipment that need to move stably.

For some environments, it may be necessary to reduce the noise during use. At this time, polyurethane and TPR casters can be considered.

Therefore, we need to choose a caster with a suitable size, a surplus load, and a specific use scenario, which is the best high-load caster.