Heat Pipe Reliability Test

/ /Heat Pipe Reliability Test

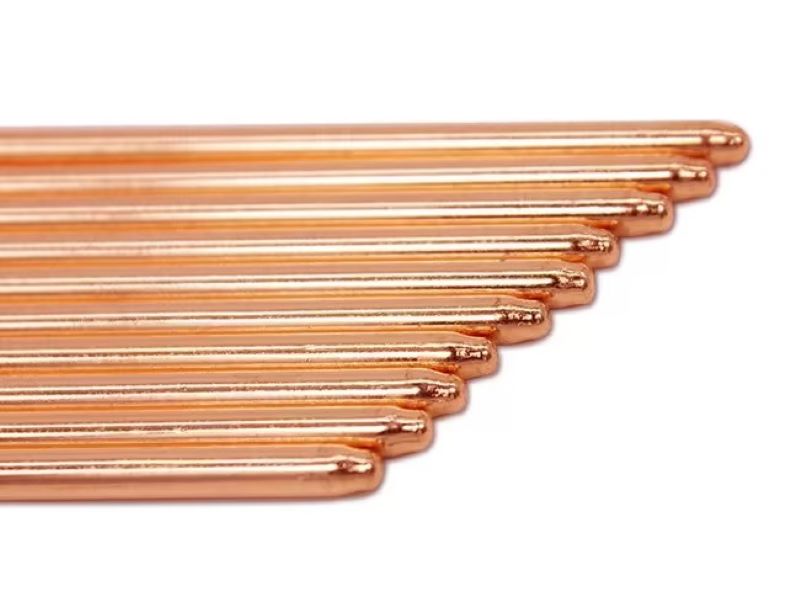

Heat pipe technology is a heat transfer element called "heat pipe" invented by G.M. rover of Los Alamos National Laboratory in 1963, which makes full use of the principle of heat conduction and the rapid heat transfer properties of the refrigeration medium, and transfers the heat of the heating object quickly to the heat source through the heat pipe. Its thermal conductivity exceeds that of any known metal. Heat pipe technology has been widely used in aerospace, military and other industries, since it has been introduced into the radiator manufacturing industry, making people change the design idea of the traditional radiator, and get rid of the single heat dissipation mode that simply relies on high air volume motor to obtain better heat dissipation effect. The use of heat pipe technology makes the radiator even if the use of low speed, low air volume motor, can also get satisfactory results, so that the noise problem plagued by air cooling heat has been well solved, opening up a new world in the heat dissipation industry.

Heat pipe reliability test conditions:

High temperature stress screening test: 150℃/24 hours

Temperature cycling test:

120℃(10min)←→-30℃(10min), Ramp: 0.5℃, 10cycles 125℃(60min)←→-40℃(60min), Ramp: 2.75℃, 10cycles

Thermal shock test:

120℃(2min)←→-30℃(2min), 250 cycles

125℃(5min)←→-40℃(5min), 250 cycles

100℃(5min)←→-50℃(5min), 2000 cycles(check once after 200 cycles)

High temperature and high humidity test:

85℃/85%R.H./1000 hours

Accelerated aging test:

110℃/85%RH/264h

Other heat pipe test items:

Salt spray test, strength (blasting) test, leakage rate test, vibration test, random vibration test, mechanical shock test, helium combustion test, performance test, wind tunnel test