High and Low Temperature Low Pressure Test Equipment|Rapid Decompression Device

/ /High and Low Temperature Low Pressure Test Equipment & Rapid Decompression Device

High and low temperature low pressure test chamber:

(1). Main technical indicators

1. Studio size: 1000D×1000W×1000H mm, the internal size is about 1000L

2. External size: about 3400D×1400W×2010H mm, excluding the controller, test hole and other prominent parts.

3. Temperature range: -70℃ ~ +150℃

4. Temperature fluctuation: ≤±0.5℃, normal pressure, no load

5. Temperature deviation: ±2℃, normal pressure, no load

6. Temperature uniformity: ≤2℃, atmospheric pressure, no-load

7. Heating rate: +20℃→+150℃≤60min

8. Cooling rate: +20℃→-65℃≤60min

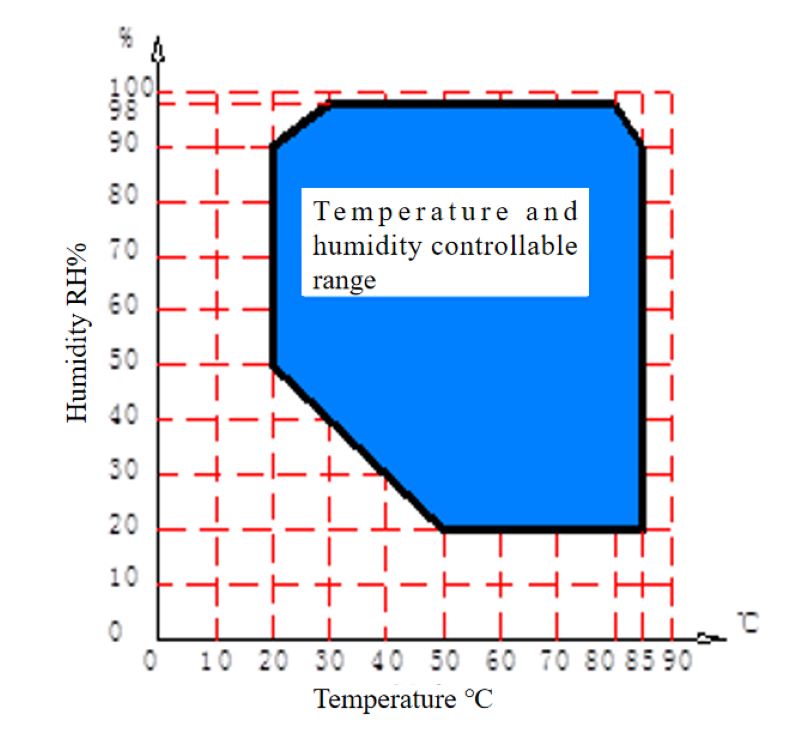

9. Humidity range: Humidity 20% ~ 98%RH (temperature +20℃ ~ +85℃ range)

10. Humidity deviation: ≤+ 2-3%RH (> 75%RH), ≤±5%RH(≤75%RH), under normal pressure and no-load conditions.

11. Pressure range: normal pressure ~ 0.5kPa

12. Pressure reduction rate: normal pressure ~ 1.0kPa≤30min

13. Pressure recovery rate: ≤10.0kPa/min

14. Pressure deviation: normal pressure ~ 40kPa:≤±2kPa, 40KPa ~ 4kPa:≤±5%kPa, below 4kPa:≤± 0.1kPa

15. Wind speed: frequency conversion adjustment

16. Power: about 50kW

17. Noise: ≤75dB (A), 1 meter away from the front of the chamber and 1.2 meters above the ground.

18. Weight: 1900Kg

(2). Rapid decompression device (optional)

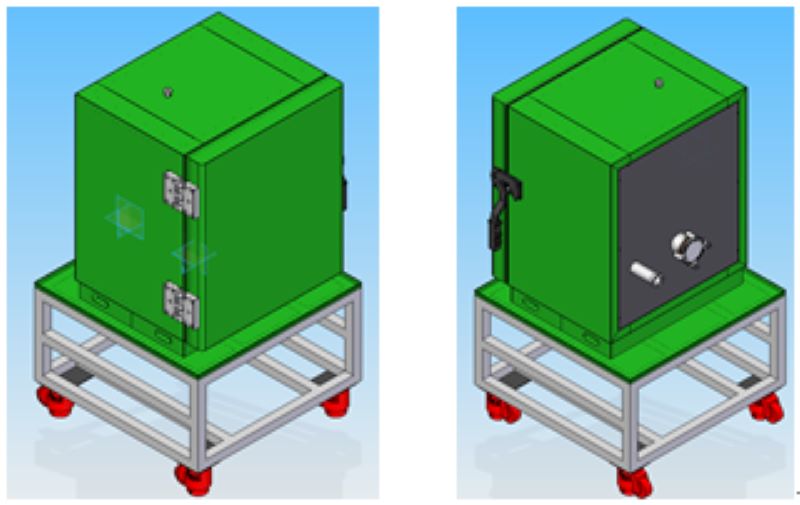

In order to meet the requirements of rapid depressurization, an independent rapid depressurization chamber is processed. The rapid depressurization chamber is composed of a shell assembly, a pressure assembly, a door assembly, an interface and a moving frame. Before rapid decompression, the user needs to connect an external pipeline.

1. Studio size: 400mm deep x 500mm wide x 600mm long; The internal wall material is processed with 3.0 SUS304/2B, and 5mm square pipe is used as the pressure reinforcement.

2. External dimension: 530mm deep ×700mm wide ×880mm long, the external wall material is made of 1.2mm cold-rolled steel plate, the surface is sprayed white (consistent with the color of the chamber);

3. A pressure sensor port is reserved at the top of the container. The control sensor port is located at the rear of the container to facilitate the quick buck device to be routed.

4. For the convenience of moving fast buck device. Install four lifting casters under the frame; The moving frame is welded by ordinary steel and sprayed on the surface.

5. Rapid decompression process: In order to improve the pumping speed of rapid depressurization chamber, the test chamber is first pumped to about 1kPa, and the electric valve connecting the test chamber equipment and the fast reducing device is opened to realize the fast reducing function, and the valve is closed when it reaches 18.8kPa. The constant pressure in the fast relief chamber can be achieved by auxiliary pumping (intake valve).

(3). Product implementation standards

1. GB/T2423.1-2008 Test A: Low temperature test

2. GB/T2423.2-2008 Test B: Low temperature test

3. GB/T 2423.3-2006 test Cab: constant temperature and humidity test

4. GB/T 2423.4-2008 test Db: alternating temperature and humidity test

5. GB/T2423.21-2008 Test M: Low pressure test method

6. GB/T2423.25-2008 test Z/AM: Low temperature/low pressure comprehensive test

7. GB/T2423.26-2008 Test Z/BM: high temperature/low pressure comprehensive test

8. General requirements for GJB150.1-2009

9. GJB150.2A-2009 Low pressure (altitude) test

10. GJB150.3A-2009 high temperature test

11. GJB150.4A-2009 low temperature test

12. GJB150.6-86 temperature-height test

13. GJB150.19-86 Temperature - humidity - height test

14. DO16F rapid decompression test

15. GB/T 10586-2006 temperature and humidity test chamber technical conditions

16. GB/T 10590-2006 high temperature low pressure test chamber technical conditions

17. GB/T 10592-2008 high and low temperature test chamber technical standard

18. GB/T 5170.1-2008 General Rules for inspection methods of environmental test equipment for electrical and electronic industry

19. GB/T 5170.2-2008 Electrical and electronic products environmental test equipment test method temperature and humidity test equipment

20. GB/T 5170.5-2008 Electrical and electronic products environmental test equipment test method temperature and humidity test equipment

GB/T 5170.10-2008 Electrical and electronic products environmental test equipment test method high temperature low pressure test equipment