The Technical Specifications of A Typical Cell on Wheels Unit

The technical specifications of a typical Cell on Wheels (COW) unit can vary based on the specific equipment and configuration used by different cellular service providers and manufacturers. However, here are some common technical specifications that you might find in a typical Cell on Wheels unit:

1. Antennas:

- Multiple high-gain directional antennas for transmitting and receiving cellular signals.

- Antenna types can include omni-directional or sector antennas, depending on coverage requirements.

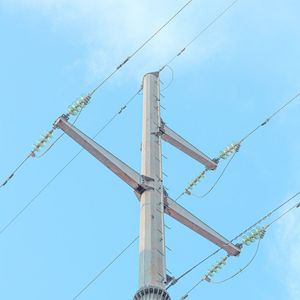

2. Mast:

- Telescoping mast for raising antennas to an elevated height for broader coverage.

- Adjustable mast height for optimizing signal propagation based on terrain and surroundings.

3. Radio Equipment:

- Base transceiver station (BTS) or radio access network (RAN) equipment for connecting to the core network.

- Multiple radio units supporting different frequency bands (e.g., LTE, 5G, etc.) for providing cellular service.

4. Backhaul Connectivity:

- Fiber optic cables, microwave links, or satellite connections for backhaul to the core network.

- High-speed data connections to ensure reliable communication between the COW and the network.

5. Power Supply:

- Generators or battery backup systems to provide power to the COW unit.

- Power distribution units for managing and distributing electrical power to various components.

6. Control and Monitoring Systems:

- Remote monitoring and management systems for real-time performance monitoring.

- Control interfaces for adjusting settings, optimizing coverage, and troubleshooting issues.

7. Environmental Protection:

- Weatherproof enclosures and equipment to protect against environmental elements.

- Climate control systems for temperature regulation in extreme weather conditions.

8. Network Compatibility:

- Support for multiple cellular network technologies such as GSM, CDMA, LTE, and 5G.

- Compatibility with different frequency bands to ensure seamless integration with existing network infrastructure.

9. Capacity and Throughput:

- Capacity planning for handling a specific number of concurrent users and data traffic.

- Throughput capabilities to support high-speed data services and multimedia applications.

10. Mobility and Transportability:

- Mounted on a mobile platform such as a truck, trailer, or container for easy transportation.

- Quick deployment and setup features for rapid deployment in emergency situations or temporary events.

These specifications can vary depending on the specific requirements of the deployment scenario, the cellular network technology being used, and the service provider's equipment choices. However, these are some common technical features you might find in a typical Cell on Wheels unit.

Learn more at www.alttower.com