PCT Test Purpose and Application (1)

/ /PCT Test Purpose and Application (1)

PCT test is generally known as pressure cooker cooking test or saturated steam test, the most important is to test the product to be tested under harsh temperature, saturated humidity (100%R.H.)[saturated water vapor] and pressure environment, test the high humidity resistance of the test product, for printed circuit board (PCB&FPC), used to carry out material moisture absorption test, high pressure cooking test... For the purpose of the test, if the product to be tested is a semiconductor, it is used to test the moisture resistance of the semiconductor package. The product to be tested is placed in a harsh temperature, humidity and pressure environment. If the semiconductor package is not good, moisture will penetrate into the package along the colloid or the interface between the colloid and the conductor frame. Popcorn effect, open circuit caused by corrosion of dynamic metallized area, short circuit caused by contamination between package pins... And other related issues.

Pressure Digester test (PCT) Structure:

The test chamber consists of a pressure vessel, including a water heater that can produce a 100% (wetting) environment. The different failures of the product to be tested after PCT test may be caused by a large amount of water vapor condensation and penetration.

Bathtub curve:

Bathtub curve (Bathtub curve, failure period), also known as bathtub curve, smile curve, mainly shows the failure rate of the product in different periods, mainly including early death period (early failure period), normal period (random failure period), wear period (degradation failure period), according to the reliability test box of environmental test. It can be divided into screening test, accelerated life test (durability test) and failure rate test. "Test design", "test execution" and "test analysis" should be considered as a whole when conducting reliability tests.

Common failure periods:

Early failure (early death, Infant Mortality Region) : imperfect production, defective materials, unsuitable environment, imperfect design. Random failure period (normal period, Useful Life Region) : external shock, misuse, changes in environmental conditions fluctuations, poor compression performance. Degradation failure period (Wearout Region) : oxidation, fatigue aging, performance degradation, corrosion.

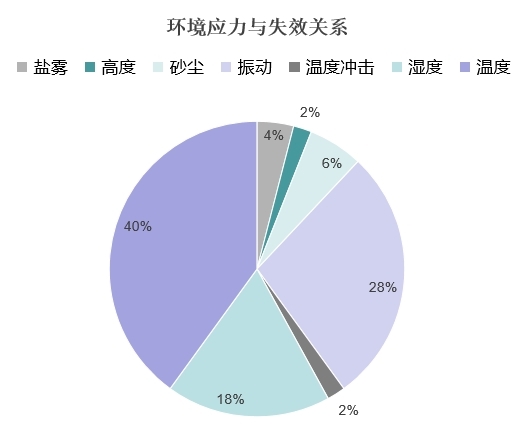

Environmental stress and failure diagram description:

According to the statistical report of Hughes Airlines, the proportion of environmental stress caused by electronic products failure, height accounted for 2%, salt spray accounted for 4%, dust accounted for 6%, vibration accounted for 28%, and temperature and humidity accounted for up to 60%, so the impact of electronic products on temperature and humidity is particularly significant, but due to the traditional high temperature and humidity tests (such as: 40℃/90%R.H., 85℃/85%R.H., 60℃/95%R.H.) takes a long time, in order to speed up the material's hypersonic rate and shorten the test time, accelerated test equipment (HAST[High accelerated life testing machine], PCT[pressure pot]) can be used to carry out relevant tests. It is also called (degenerate failure period, wear period) test.