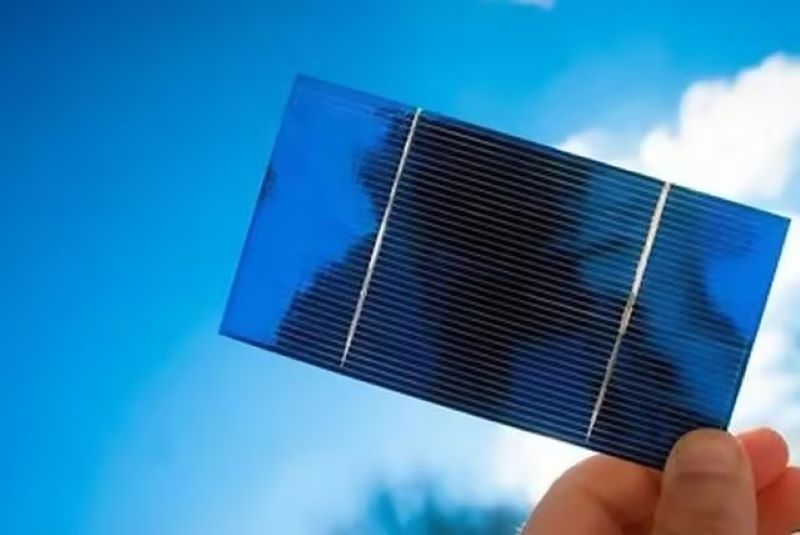

Thin Film Solar Cell

/ /Thin Film Solar Cell

Thin film solar cell is a kind of solar cell manufactured by thin film technology, which has the advantages of low cost, thin thickness, light weight, flexibility and bendability. It is usually made of semiconductor materials such as copper indium gallium selenide (CIGS), cadmium telluride (CdTe), amorphous silicon, gallium arsenide (GaAs), etc. These materials have high photoelectric conversion efficiency and can generate electricity under low light conditions.

Thin film solar cells can be used in inexpensive glass, plastic, ceramics, graphite, metal sheet and other different materials as substrates to manufacture, forming a film thickness that can generate voltage only a few μm, so the amount of raw materials can be significantly reduced than silicon wafer solar cells under the same light receiving area (thickness can be lower than silicon wafer solar cells more than 90%). At present, the conversion efficiency of up to 13%, thin film solar cells are not only suitable for flat structure, because of its flexibility can also be made into non-plane structure, has a wide range of application prospects, can be combined with buildings or become a part of the building body.

Application of thin film solar cell product:

Translucent solar cell modules: Building Integrated Solar Energy Applications (BIPV)

Application of thin film solar energy: portable folding rechargeable power supply, military, travel

Applications of thin film solar modules: roofing, building integration, remote power supply, defense

Features of thin film solar cells:

1. Less power loss under the same shielding area (good power generation under weak light)

2. The loss of power under the same illumination is less than that of wafer solar cells

3. Better power temperature coefficient

4. Better light transmission

5. High cumulative power generation

6. Only a small amount of silicon is needed

7. There is no internal circuit short circuit problem (the connection has been built in the series battery manufacturing)

8. Thinner than wafer solar cells

9. Material supply is secure

10. Integrated use with building materials (BIPV)

Solar cell thickness comparison:

Crystalline silicon (200 ~ 350μm), amorphous film (0.5μm)

Types of thin film solar cells:

Amorphus Silicon (a-Si), Nanocrystalline Silicon (nc-Si), Microcrystalline Silicon, mc-Si), compound semiconductors II-IV [CdS, CdTe(cadmium telluride), CuInSe2], Dye Sensitized Solar cells, Organic/polymer solar cells, CIGS (Copper indium selenide)... Etc.

Thin-film solar module structure diagram:

Thin film solar module is composed of glass substrate, metal layer, transparent conductive layer, electrical function box, adhesive material, semiconductor layer... And so on.

Reliability test specification for thin film solar cells:

IEC61646(Thin-film solar photoelectric module test standard), CNS15115(thin-film silicon onshore solar photoelectric module design validation and type approval)

Temperature & humidity test chamber of Lab Companion

Temperature & humidity test chamber series, passed the CE certification, offer 34L, 64L, 100L, 180L, 340L, 600L, 1000L, 1500L and other volume models to meet the needs of different customers. In design, they use environment-friendly refrigerant and high-performance refrigeration system, parts and components are used in the international famous brand.